At Acrylic Aquarium Co., we pride ourselves on crafting bespoke acrylic aquariums tailored to your exact specifications. We're not just building tanks; we're creating aquatic masterpieces. Our expertise lies in meticulously constructing high-quality, durable acrylic aquariums, paying close attention to every detail from initial design to final installation.

We believe in partnering closely with our clients, ensuring that each aquarium perfectly complements its environment and showcases the beauty of the underwater world.

Choose Acrylic Aquarium Co. for an aquarium that's as unique and stunning as the marine life it will house.

My fascination with aquariums began as a child, but it wasn't the small glass boxes that captivated me. I was drawn to the grand public aquariums, the massive displays teeming with life, the sheer scale of the underwater worlds they contained. I dreamed of creating such awe-inspiring environments myself. While glass offered a glimpse into these ecosystems, I quickly recognized its limitations, particularly when it came to large-scale projects. The fragility, the weight, the limited design flexibility – all presented challenges. I envisioned a better way, a way to build truly monumental aquariums with unparalleled clarity, strength, and design freedom. That vision, fueled by the potential of acrylic, led to the birth of Acrylic Aquarium Co.

We believe that every aquarium should be a masterpiece. We use only the highest-grade acrylic, meticulously crafted by skilled artisans, to ensure exceptional clarity, strength, and longevity. Our aquariums are built to last, providing a breathtaking centerpiece for years to come.

Building an aquarium is a journey, and we're with you every step of the way. From initial consultation to final installation, our dedicated team provides personalized support, answering your questions and addressing your concerns promptly and professionally. We're committed to exceeding your expectations.

We're not just building tanks; we're creating living works of art. We constantly strive to push the boundaries of aquarium design, exploring new shapes, sizes, and features to create truly unique and captivating displays. We embrace creativity and collaboration, working closely with our clients.

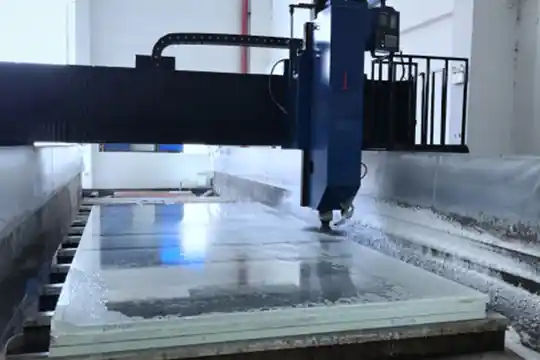

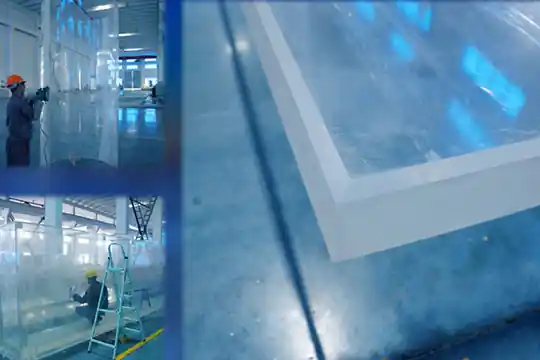

We specialize in designing, building, and installing large, custom acrylic aquariums. Our team boasts over 20 years of combined experience in the aquarium industry. We've honed our skills in acrylic fabrication, mastering techniques like cutting, chamfering, grinding & polishing. This expertise allows us to create seamless, crystal-clear aquariums of any size and complexity. We're particularly passionate about public aquarium displays. Our commitment to continuous learning and innovation ensures that we remain at the forefront of aquarium technology, delivering the most advanced and aesthetically pleasing aquariums available.

Acrylic Aquarium Co. is a global provider of premium acrylic aquariums, known for our innovative designs and exceptional quality. Our state-of-the-art manufacturing process, combined with a dedication to customer satisfaction, makes us the ideal choice for your next aquarium. Discover the steps involved below.

We maintain a stock of high-quality liquid acrylic (MMA) as our raw material. This liquid is then transformed into solid acrylic sheets through a process called polymerization, creating the building blocks for your aquarium.

In the early stages of polymerization, the liquid acrylic molecules begin to clump together. This "initial aggregation" is a key step in forming the final acrylic structure, influencing its strength and clarity.

The newly formed acrylic sheets undergo initial milling to achieve a consistent thickness and smooth surface, preparing them for further processing.

For thicker aquarium panels, multiple sheets are bonded together using a specialized "thickness compound." This creates the necessary strength to hold large volumes of water.

After the thickness compounding, the bonded sheets are milled again to ensure perfect uniformity and smoothness across the now thicker panel.

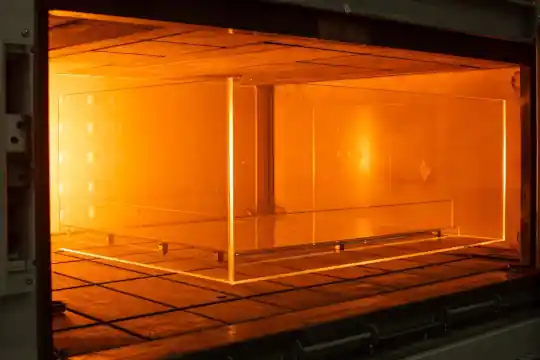

The acrylic sheets are carefully heated in an oven in a process called annealing. This relieves any internal stresses in the material, increasing its strength and preventing cracking.

The acrylic sheets are precisely cut to the desired shapes for your aquarium. Edges are chamfered (slightly angled), ground smooth, and then polished to a crystal-clear finish.

Every piece of acrylic is thoroughly inspected for any imperfections. This rigorous quality control ensures that only the highest quality components are used in your aquarium.

The finished acrylic components are carefully packaged to protect them during transport and ensure they arrive at your location in pristine condition.